Revolutionizing supply chain operations with digital transformation and automation

The Role of Digital Transformation in Supply Chains

What is Digital Transformation?

Digital transformation refers to the integration of digital technologies into all areas of business operations, fundamentally changing how organizations deliver value to customers. In the context of supply chains, it emphasizes automation, data-driven decision-making, and the elimination of manual inefficiencies.

Benefits of Digital Transformation in Supply Chains

- Enhanced Efficiency: Automation reduces reliance on human intervention.

- Improved Visibility: Digital tools provide end-to-end insights into operations.

- Agility: Enables quicker responses to market fluctuations.

Automation in Supply Chain Management

Defining Automation

Automation in supply chains involves using technology to perform repetitive tasks, optimize workflows, and minimize human errors. Robotics, AI-driven software, and intelligent systems play crucial roles in this area.

Key Areas Impacted by Automation

- Inventory Management: Automating stock tracking prevents overstocking or understocking.

- Order Fulfillment: Speeds up processing times and ensures accuracy.

- Logistics and Transportation: Automates routing for efficient delivery.

How Artificial Intelligence is Revolutionizing Supply Chains

Predictive Analytics

AI processes historical and real-time data to predict demand trends, enabling better inventory planning and minimizing waste.

Enhanced Decision-Making

AI-powered algorithms facilitate autonomous decision-making, such as rerouting shipments during disruptions or suggesting cost-effective suppliers.

Fraud Detection and Risk Mitigation

AI can identify unusual patterns that might indicate fraud or potential risks, ensuring secure operations.

The Internet of Things (IoT): Enabling Real-Time Monitoring

IoT in Supply Chains

IoT connects devices and systems across the supply chain, enabling seamless communication and data sharing. Examples include GPS tracking systems and smart sensors.

Applications of IoT

- Real-Time Tracking: Ensures visibility of goods in transit.

- Predictive Maintenance: IoT sensors detect potential equipment issues before they escalate.

- Condition Monitoring: Monitors temperature, humidity, and other conditions to ensure product quality.

Machine Learning for Continuous Improvement

Learning from Data

Machine Learning (ML) algorithms analyze patterns in supply chain data, offering actionable insights and recommendations.

Forecasting and Demand Planning

ML improves the accuracy of demand forecasts, helping businesses anticipate customer needs more effectively.

Supplier Relationship Management

Analyzes supplier performance to identify reliable partners and optimize procurement processes.

Challenges in Implementing Digital Transformation and Automation

- High Initial Costs: Investment in advanced technologies can be substantial.

- Data Integration Issues: Combining legacy systems with new technologies can be complex.

- Workforce Adaptation: Employees may require upskilling to work with new systems.

Case Studies: Success Stories in Digital Supply Chains

Amazon’s Predictive Analytics

Amazon uses AI to forecast customer demands and optimize inventory, ensuring rapid delivery times.

Maersk’s IoT-Enabled Shipping

Maersk utilizes IoT sensors to monitor shipping conditions, reducing spoilage in perishable goods.

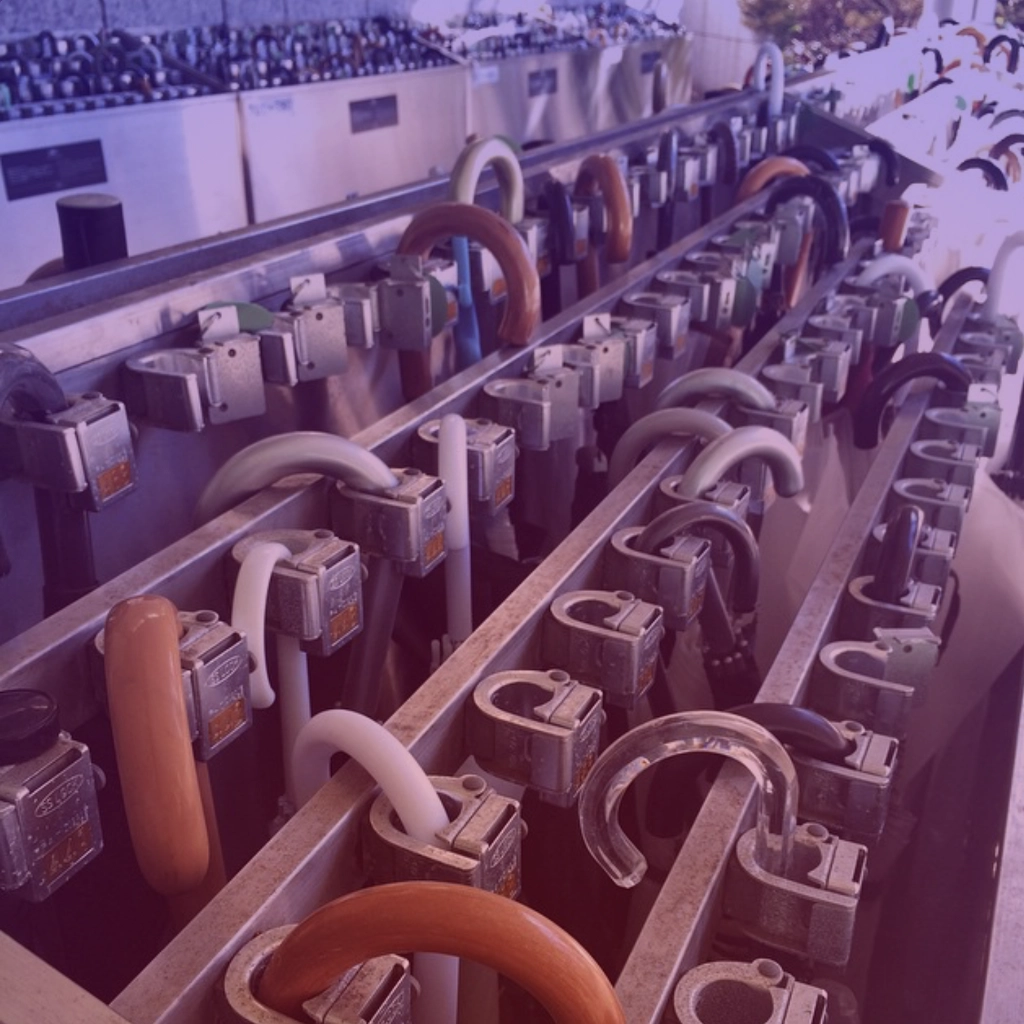

Tesla’s Automated Manufacturing

Tesla’s robotic systems streamline production lines, enhancing efficiency and precision.

The Future of Digital Supply Chains

As technologies evolve, the supply chain landscape will continue to transform. AI, ML, and IoT, coupled with emerging innovations like blockchain and augmented reality, promise even greater transparency, efficiency, and customer satisfaction. Businesses that embrace these changes today will be better positioned to lead tomorrow.

Conclusion

Digital transformation and automation are no longer optional but essential for modern supply chains. By leveraging AI, ML, and IoT, businesses can achieve predictive capabilities, real-time visibility, and autonomous decision-making. These advancements drive resilience, agility, and competitiveness in a complex global market. The time to embrace the digital revolution is now.